Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

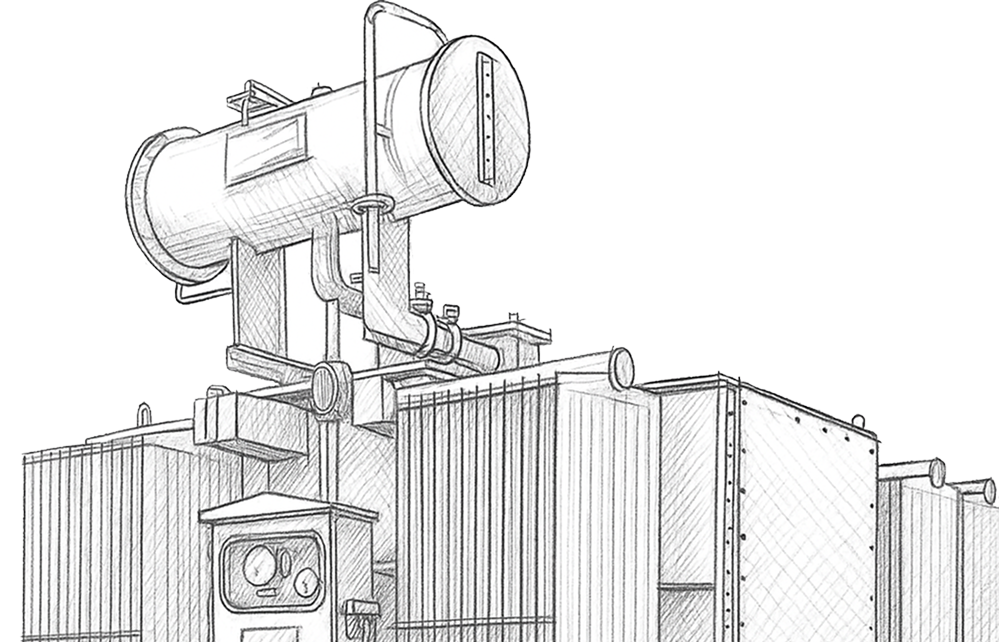

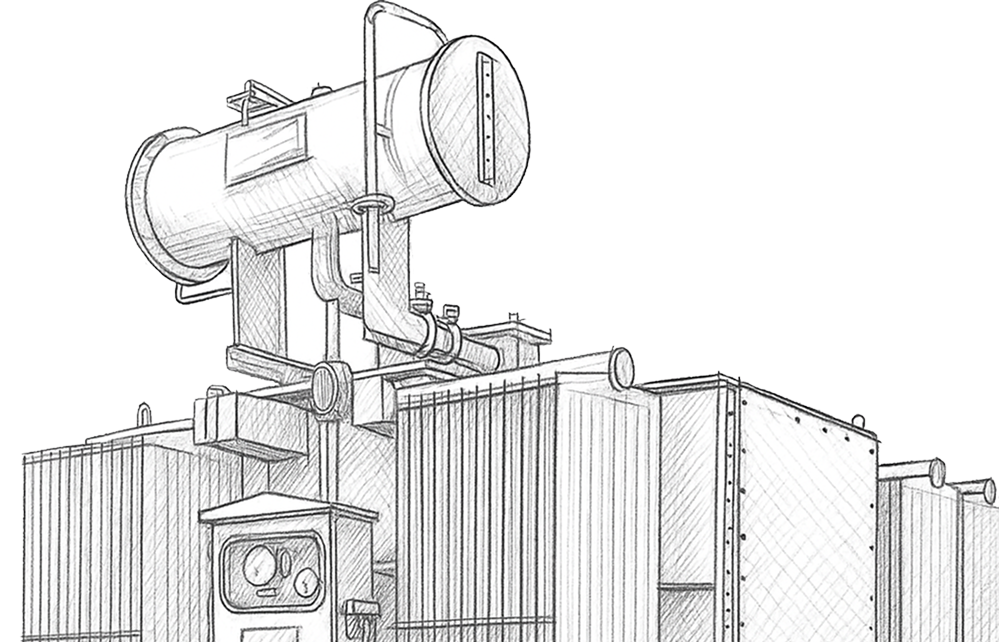

A power transformer is an electrical device designed to transfer energy between circuits while maintaining a constant frequency. As a static machine, it operates without moving or rotating parts, relying on the principle of mutual induction to efficiently transmit power through an AC supply.

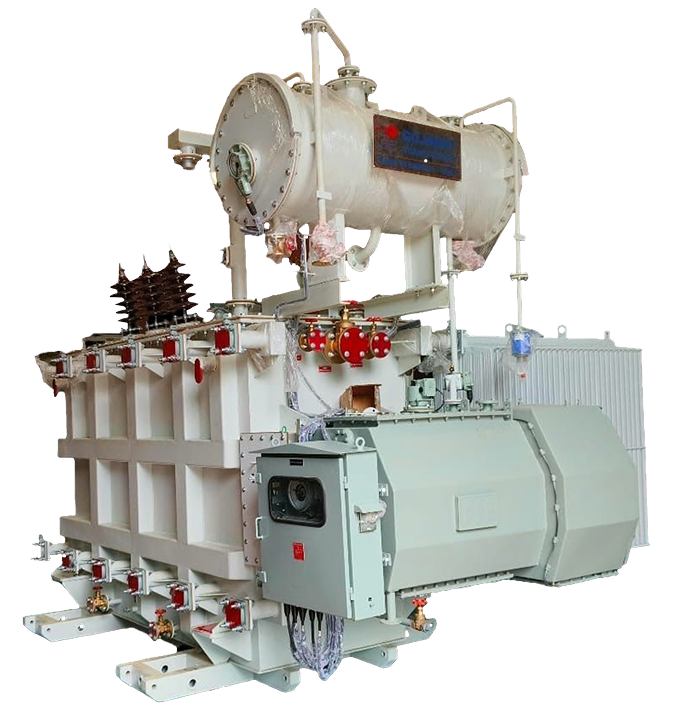

World-class power transformers are manufactured in Vadodara, in the state of Gujarat by GUJARAT TRANSFORMERS. The brand is well known because of its performance in the market for 55 years. These industrial steam turbines can cater to 45 MW capacities up to 150 MW.

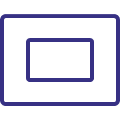

Located above the main tank, it stores and regulates transformer oil expansion.

The main enclosure that houses the core, windings, and other vital components.

Provides a low-reluctance path for magnetic flux, ensuring efficient energy transfer.

A protective device that detects internal faults by sensing gas accumulation.

Contains silica gel to absorb moisture from the air entering the transformer, preventing oil contaminatio.

Copper coil turns responsible for voltage transformation, classified as primary and secondary windings.

Facilitate heat dissipation by cooling the transformer oil.

Adjusts the voltage levels to maintain a stable output.

Used in transformers above 50 KVA to monitor internal temperature.

Positioned above the conservator, it releases pressure in case of internal faults to prevent transformer damage.

Designing efficient magnetic components for transformers is crucial for modern electronics. Key considerations include:

Ensure stable input and output voltage ranges.

Calculate output power, current, and switching frequency.

Select the right mode and maintain IC duty cycle efficiency.

Meet regulatory standards for safe operation.

Optimize performance for ambient temperature conditions.

Design within spatial constraints without compromising efficiency

Efficient voltage regulation and transformation.

Supports seamless power transmission and distribution.

High reliability with no moving parts.

Galvanic isolation ensures safety.

Long lifespan and cost-effective.

Low noise operation for minimal environmental impact.

Reliable Transformer Solutions for Every Industry

Years of expertise in designing high-performance transformers with innovation.

Transformers Tailored for quality and performance across industries.

Clients Relying on our transformers for consistent performance and innovation.

Skilled Professionals Delivering exceptional transformer solutions across various industries.

Reliable Transformer Solutions for Every Industry

Years of expertise in designing high-performance transformers with innovation.

Transformers Tailored for quality and performance across industries.

Clients Relying on our transformers for consistent performance and innovation.

Skilled Professionals Delivering exceptional transformer solutions across various industries.

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin