Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

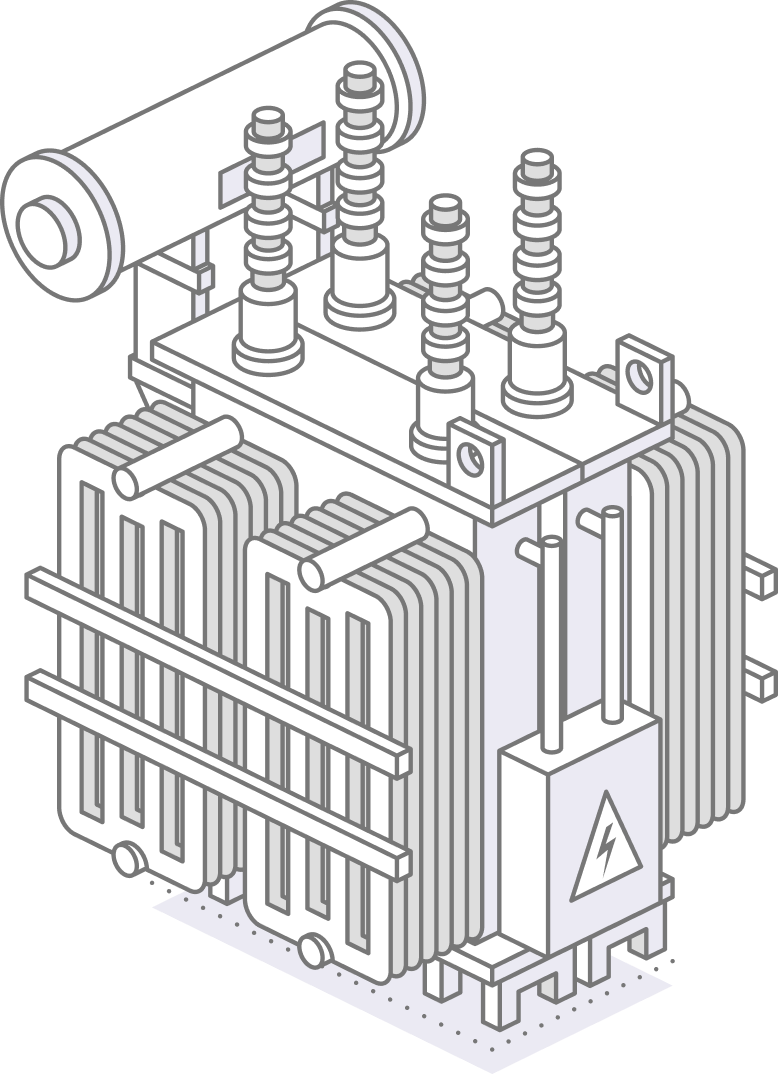

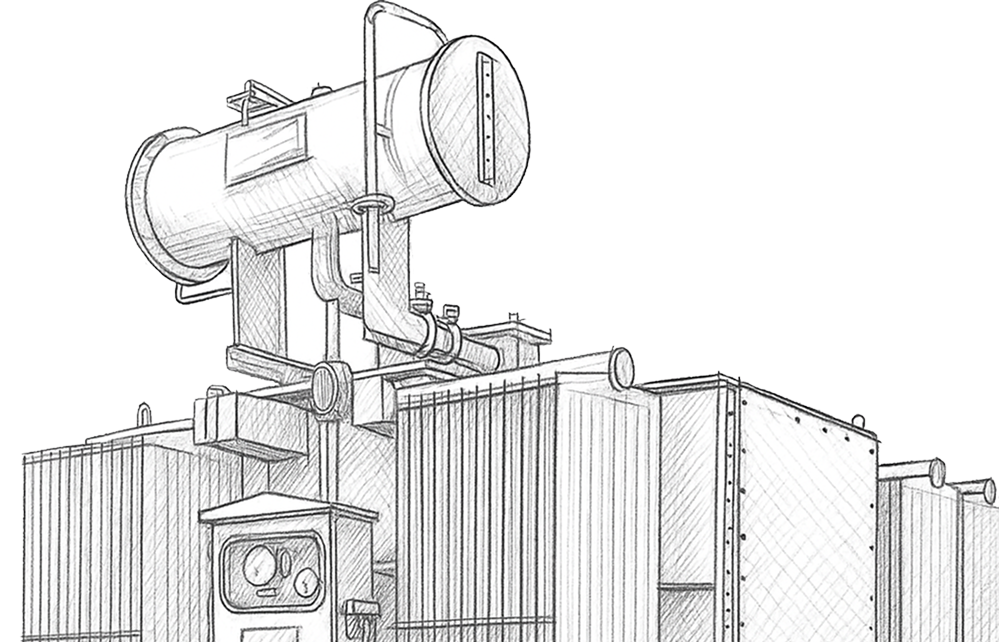

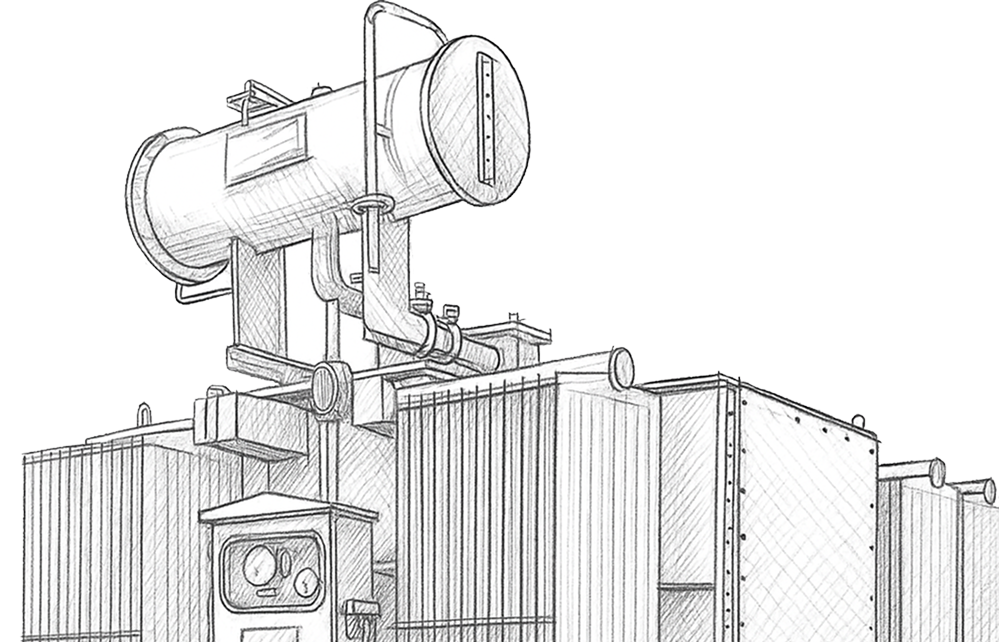

An electrical device called a distribution transformer reduces high-voltage energy from transmission lines to a level that is suitable for use in residences, workplaces, and industrial settings. By guaranteeing that electricity is delivered to end consumers safely and effectively, it plays an essential role in power distribution.

Currently, the most challenging decision for most is to find a suitable location to install a Distribution Transformer. The energy departments require these transformers to meet the load, load centre, possibility, and other requirements.

Distribution Transformers were introduced to the market 55 years ago when the city of Vadodara, Gujarat, began manufacturing them under Gujarat Transformers. It was also made to be a subtype of an isolation transformer. They function to modify voltage into a standard output of 240V/120V to be easily used in energy distribution.

Space-efficient design ensuring reliable and durable performance.

Converts 33kV to a lower voltage for safe power distribution.

Functions at 60-70% capacity for stable energy supply.

Provides 3-5 points for precise voltage regulation and control.

Enhances insulation, prevents overheating, and ensures efficient operation.

Manages oil expansion, maintaining system stability and performance.

Detects internal faults early, preventing transformer failures and damage.

Absorbs moisture, keeping transformer oil dry and contamination-free.

Thermometer and relief system safeguard against overheating damage.

Ensures heat dissipation, prevents energy loss, and maintains connectivity.

The design of a Distribution Transformer includes the following components:

The primary section, electricity enters the system through them.

The secondary section connects the transformer with the electric instruments in use.

The primary winding draws energy for supply, and the secondary transmits it to the equipment.

The path of magnetic flux eliminates heat.

Residential & Commercial Use

Voltage Step-Down

Power Distribution

Industrial & Domestic Supply

Renewable Energy Integration

Hospitals & Healthcare Facilities

Reliable Transformer Solutions for Every Industry

Years of expertise in designing high-performance transformers with innovation.

Transformers Tailored for quality and performance across industries.

Clients Relying on our transformers for consistent performance and innovation.

Skilled Professionals Delivering exceptional transformer solutions across various industries.

Reliable Transformer Solutions for Every Industry

Years of expertise in designing high-performance transformers with innovation.

Transformers Tailored for quality and performance across industries.

Clients Relying on our transformers for consistent performance and innovation.

Skilled Professionals Delivering exceptional transformer solutions across various industries.

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin