Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

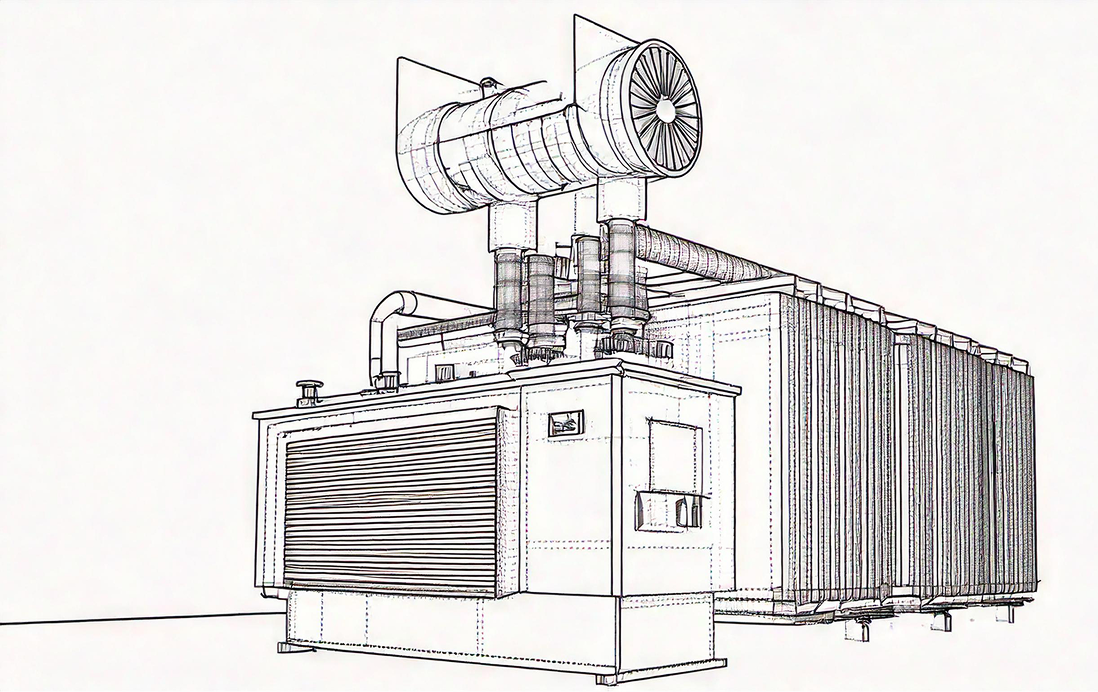

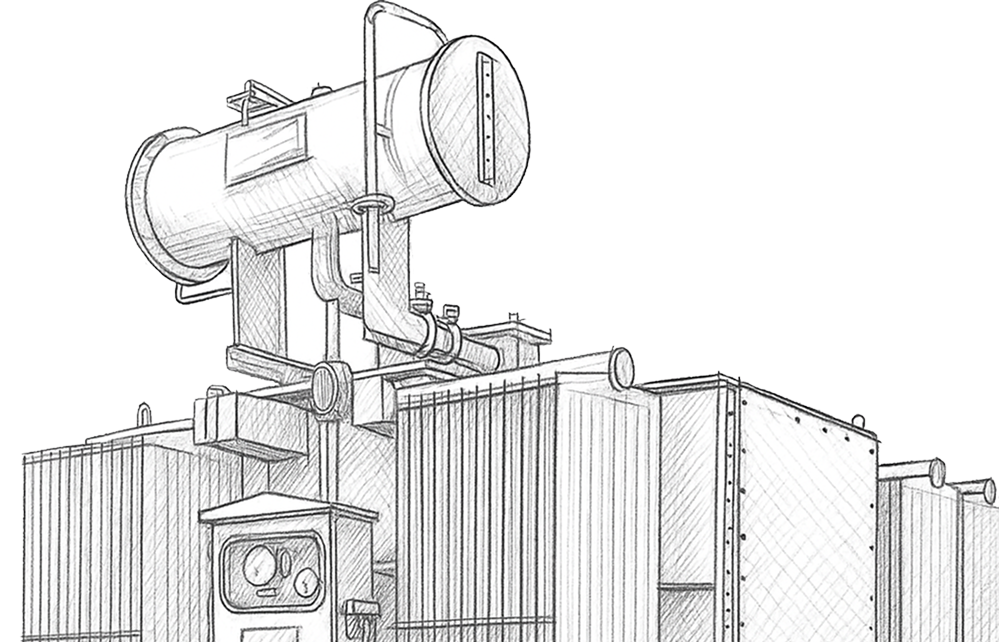

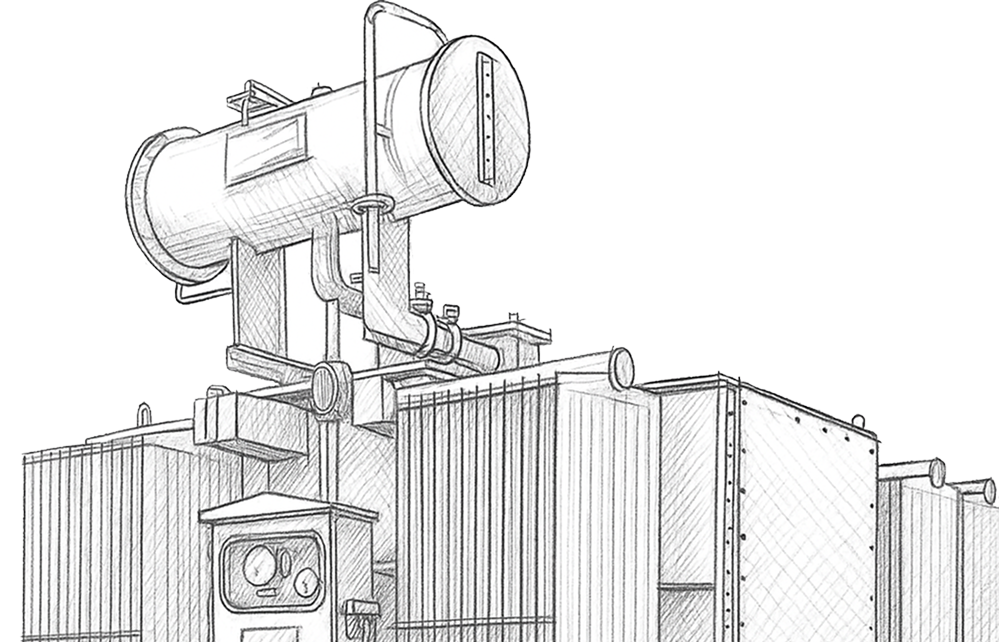

A furnace transformer is designed to increase or decrease AC voltage to suit the heating system's requirements. It transfers electrical energy from the circuit to the induction process, ensuring proper voltage regulation.

Depending on the furnace's needs, the transformer can either amplify or reduce the electricity within the system. These transformers were originally manufactured in Vadodara, Gujarat, and have become popular over time. To date, their performance remains unmatched.

Ranges from a few MVA to 150 MVA.

Secondary currents can exceed 100,000 A.

Achieved by parallel winding sections and internal bus bars.

Output voltage adjusts to control power input.

Regulated over a 3:1 ratio for performance.

Managed via winding taps and switching.

Enables large kVA increments.

Ensures stable current for arc furnaces.

Enhances performance below 7,500 kVA.

If a transformer issue is suspected, look for these warning signs:

Burn marks or bulges may signal the need for a replacement. Some cases require only repairs, which professionals can handle.

While some noise is normal, excessive humming may result from the iron core and laminations contracting or expanding.

If the furnace transformer is faulty, the circuit breaker may trip to prevent a voltage surge that could damage furnace components.

The system may shut down to protect itself from power supply damage. Verify if this is a normal occurrence or if the power supply requires repair.

Withstands high mechanical and thermal stresses

Easily manages high currents

High low-voltage variation, ideal for furnace applications

100% standby capacity

OFWF cooling system

Resilient against stress from electric arcs

Reliable Transformer Solutions for Every Industry

Years of expertise in designing high-performance transformers with innovation.

Transformers Tailored for quality and performance across industries.

Clients Relying on our transformers for consistent performance and innovation.

Skilled Professionals Delivering exceptional transformer solutions across various industries.

Reliable Transformer Solutions for Every Industry

Years of expertise in designing high-performance transformers with innovation.

Transformers Tailored for quality and performance across industries.

Clients Relying on our transformers for consistent performance and innovation.

Skilled Professionals Delivering exceptional transformer solutions across various industries.

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin

Lorem Ipsum tempor sed. Nunc sollicitudin sollicitudin